Hibot collaborates with Vinçotte to provide cutting-edge robotics technology for the inspection of infrastructure

Vinçotte’s inspection operations will benefit from hibot’s revolutionary robotic systems

Hibot Corp., an innovative robotics start-up and pioneer of the RaaS (Robot as a Service) model for the inspection and maintenance of industrial infrastructure, announced that it collaborates with Vinçotte. This collaboration will see hibot providing some of its robotic inspection system, such as Float Arm and the Boiler Inspection System, to be used by Vinçotte in inspection missions mostly in Belgium, the Netherlands, Luxemburg and other European regions.

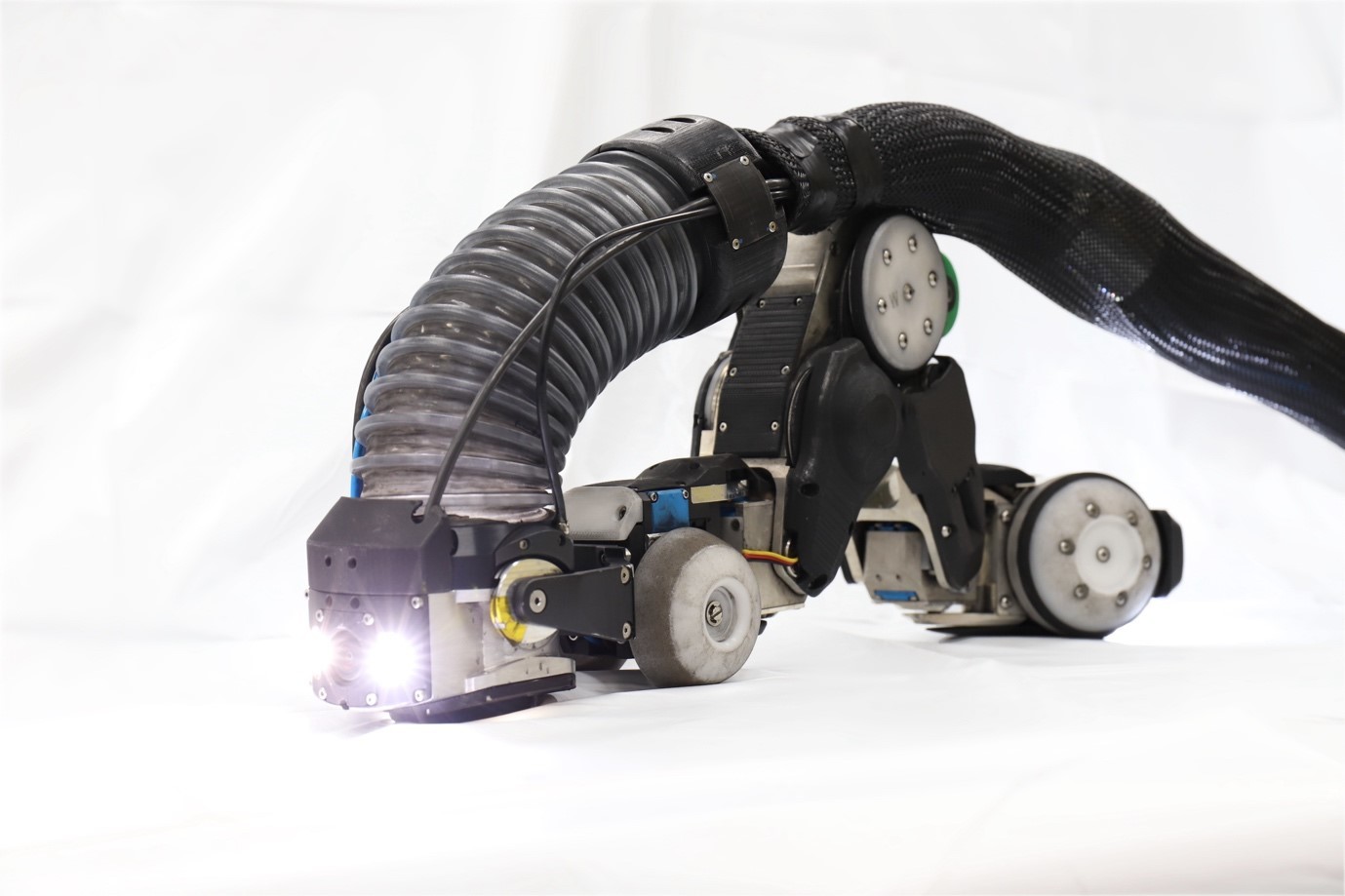

As early adopters of the robotic platforms offered by hibot, Vinçotte will benefit from cutting-edge technology that has been developed and fine-tuned over several years in harsh environments. Some of the robotic inspection systems being made available by hibot are Float Arm, a long-reach manipulator with multiple links that can operate in confined spaces with obstacles (such as pressure vessel tanks and pipe racks), and the Boiler Inspection System, a snake-like robot that brings a multi-channel ultrasonic sensor and inserts it in boiler water pipes to inspect their wall thickness.

The Float Arm makes it possible to perform highly detailed inspection inside pressure vessel tanks, where human entrance is severely limited, or event prohibited, due to safety concerns. The robot has a multi-link, modular design which enables it to navigate through obstacles and inspect pipe racks in high locations or other difficult-to-reach assets, drastically cutting inspection time and reducing the need for scaffolding almost to zero. Float Arm is equipped with a high-definition inspection camera, multiple navigation cameras, 3D sensors and ultrasonic probes for wall thickness measurements. This portfolio of sensors will soon be expanded with a probe for corrosion under insulation measurement.

The Boiler Inspection System, on the other hand, performs wall thickness measurements of the water pipes coming down from the head drum. Those pipes are often exposed to high temperatures and corrosive gases, which may lead to premature corrosion. The Boiler Inspection System is able to enter the head drum and insert a sensor with multiple ultrasonic probes in the water pipes. As the sensor moves along the pipe, it generates a 2D map showing the pipe thickness, and any irregularity (such as corrosion or pitting) becomes immediately visible. With the Boiler Inspection System, the time needed to prepare and inspect those pipes can be brought down from a few weeks to a couple of days.

As first TIC users, Vinçotte aims to unleash the full potential of hibot’s robotic systems for inspection of infrastructure, setting new trends in the field and developing know-how that will lead to the adoption of other robotics systems and even more advanced technologies in the near future. Currently the first tests with the Float Arm have been conducted at Vinçotte. The next stage is to continue testing both robots in the field during actual missions. Ultimately the goal is to create a team of qualified NDT specialists who can operate the robots and execute inspections.

“This collaboration with Vinçotte will revolutionize the field of infrastructure inspection,” said Michele Guarnieri, co-founder and CEO of hibot. “Not only will it provide advanced robotic technologies to the market, but also enable the validation and acceptance of bleeding-edge solutions that may seem ahead of their time, but are actually just around the corner. The field of inspection of infrastructure has a real need for such innovative solutions.”

Martijn Cuyx, Innovation Manager at Vinçotte, adds: “At Vinçotte we understand that equipment failure or faulty infrastructure can lead to dangerous working conditions and costly unplanned downtime to repair. Today, for the most part, a time-based inspection approach is used to examine these critical assets which traditionally incur lengthy and costly preparations & shutdowns and unsafe working conditions for the inspector. In addition, many industries see digital transformation as a priority for their operations. This means inspections need to become more and more digitalized to allow better decision-making on part of the asset owners. As such we at Vinçotte are constantly searching for solutions that minimize asset downtime and provide reliable digital data in the safest possible manner. The robot solutions developed by hibot exactly fit that philosophy. We are thus looking forward to expanding our collaboration with hibot and integrating their solutions within our operations.”

About hibot #

Established in 2004, hibot is a robotics start-up originating from within the Tokyo Institute of Technology, committed to realizing a safer and more sustainable world by creating new trends in infrastructure inspection and maintenance. Hibot develops and utilizes AI-powered remotely controlled robots that allow human beings to be removed from dirty, dangerous or demanding working environments. Hibot’s robots have been applied in search and rescue missions, and have been used during decommissioning work at Japan’s Fukushima No. 1 nuclear power plant.

About Vinçotte #

Vinçotte is the largest inspection, auditing and certification company in Belgium and offers over 220 services in the fields of inspection, certification, conformity assessment and training. Its 2,000 employees dedicate themselves every day to increasing the safety, efficiency and sustainability of society. Vinçotte is active in the Benelux region and conducts over 5,000 inspections each day. It has more than 100,000 clients, comprising multinationals, SMEs, sole traders and individuals.

Vinçotte is active in various sectors, including the manufacturing industry, chemical & petrochemical industries, pharmaceutical sector and energy, automotive, food and construction sectors.