Vinçotte uses robots for tank inspection at Belgoprocess

Vinçotte, member of the KIWA group, was contracted by Belgoprocess for visual inspection and thickness measurements of bunkered storage tanks at their wastewater treatment plant on site 2. Due to the ionizing radiation and the risk of radioactive contamination, a remote inspection with industrial robotics was the logical solution.

The trusted choice with proven expertise

Vincotte participated in the tender, issued by Belgoprocess and was selected for a multitude of reasons. Not only had Belgoprocess previously collaborated with Vinçotte with excellent results, but in this case Vinçotte's proposed solution, using smart tools, stood out.

“Innovative ideas had a lot of weight in this tender,” says Frankie Vermierdt, project lead for Belgoprocess. “The proposal to use a robot was new, but above all realistic and well thought out.”

Ready to go

Most of the storage tank is stainless steel, which precluded the use of magnetic crawlers. Suction-based crawler robots and UAVs (drones) were deemed unsuitable due to the high risk of contamination in such environments.

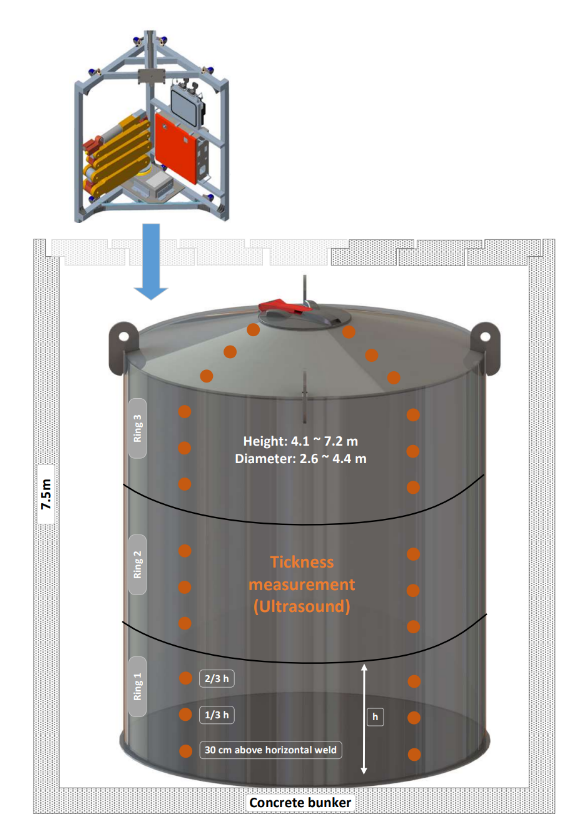

Belgoprocess and Vinçotte combined their experience to overcome these and other obstacles, while Vinçotte's robotics partner hibot supplied the Floatarm, an articulated arm robot for multifunctional NDT inspections (NDT stands for Non Destructive Testing) as a solution. This arm can be packaged against contamination and equipped with the appropriate sensor payloads. Furthermore, a cage was developed to provide the robot with access to the narrowest corners of the deep bunkers using the existing overhead cranes.

“Setting up the prototype and further implementation on our installation went extremely smoothly,” Frankie continues, “thanks to the excellent communication and interaction between the teams at Belgoprocess, Vinçotte and hibot.”

Successful inspection

No major preparations, such as building scaffolding or other general protective measures, were required for the inspection. Furthermore, thanks to the Floatarm, the risk associated with working at great heights can be significantly reduced. And of course, the exposure of personnel to ionizing radiation and the risk of radioactive contamination is kept to a minimum. In short, an inspection that meets all standards for industrial safety, occupational safety, and health. A perfect example of industrial automation.

All measurements of the remote inspection by the Floatarm were digitized and related to a coordinate system and point cloud.

“The collaboration with Vinçotte went very smoothly, through all phases of the project. We are very satisfied with the results of the Floatarm inspection,” Frankie concludes. “We are already preparing for the next project and look forward to continue our collaboration.”

Read more about robotic inspections with the Floatarm

Check out our robotic inspection service pageMore about our partnership with hibot

Read the press releaseFloatarm @ Swedish Conference on Nuclear Power 2023 - 28 November

Come find us at the Swedish Conference on Nuclear Power 2023, where we will tell you all about our experiences with the Floatarm.

Kiwa - Swedish Conference on Nuclear Power 2023