MRT – Magnetic Rope Testing

From towering cranes lifting heavy loads to cable cars transporting passengers through breathtaking landscapes, cables play a crucial role in numerous industries. However, worn and damaged cables pose a significant safety risk, with potentially catastrophic consequences.

While visual inspections are essential, they often miss crucial internal wear and tear, leaving people and production vulnerable to unexpected failures. Thanks to Magnetic Rope Testing (MRT), there is now an innovative solution for reliable and comprehensive cable inspection.

Magnetic Rope Testing (MRT) is a non-destructive testing (NDT) technique that uses the power of magnetism to detect internal and external defects in cables. By fully magnetizing the cable section, MRT creates a uniform magnetic field that is then used to detect defects.

How does Magnetic Rope Testing work?

Principle: MRT is based on the principles of magnetic flux leakage (MFL). When a ferromagnetic material, such as a wire rope, is magnetised, the magnetic field flows along the length of the material. However, when a fault (such as corrosion or a crack) is present in the material, the magnetic field leaks out of the material at the site of the fault.

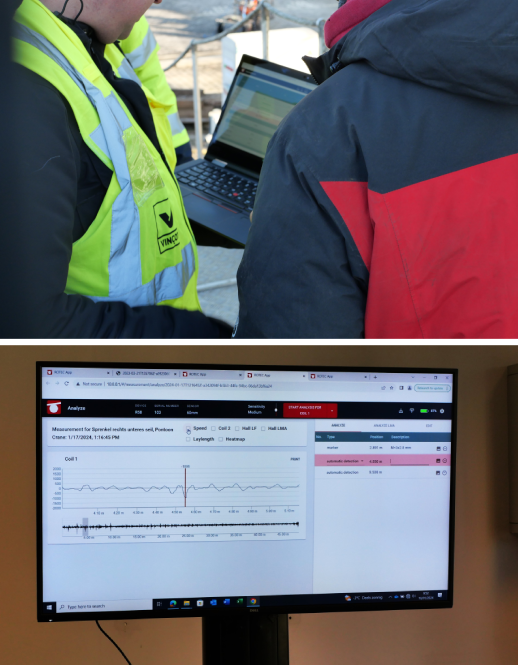

Equipment: The MRT inspection equipment consists of a magnetising unit, a sensor array and a data collection system. The magnetising unit generates a magnetic field that magnetises the cable. The probe or sensor array is then used to detect magnetic flux leakage from the surface of the cable.

Inspection process: During inspection, the magnetising unit is clamped around the cable and the cable is magnetised. The probe or sensor array is then either moved along the length of the cable or the cable is moved by the sensor array. Changes in the magnetic field caused by leakage are detected.

Data analysis: the data collected by the sensor array is analysed to identify any indications of faults or defects in the cable. Changes in the strength or pattern of the magnetic field may indicate the presence of defects such as corrosion, wear or broken wires.

Interpretation: Trained inspectors interpret the data to determine the severity and location of any detected faults. This information helps asset owners make informed decisions about the condition of their wire cables and whether any maintenance or replacement is needed.

- Non-destructive: MRT allows inspection without damaging the cable

- Comprehensive: Unlike a visual inspection, an MRT inspection detects both external and internal defects simultaneously, providing a complete picture of the cable's health.

- Fast and efficient: Compared to visual inspections, MRT offers fast testing with minimal disruption to operations.

- Highly accurate: Detects even small anomalies and provides a reliable assessment of cable condition.

By looking beyond the surface, MRT enables you to proactively address potential problems before they escalate into catastrophic failures. This translates into more safety, less downtime and peace of mind for industries that rely on the reliable performance of your cables.

ISO standard 4309-2017 - which describes all guidelines for the installation, maintenance and inspection of wire ropes in cranes and hoists - recommends the use of MRT as an additional inspection method.

As such, MRT can be done as part of the required visual inspection , with the advantage of providing a thorough examination of cables and validating findings through plots and heatmaps.

Case study - The Port of Antwerp-Bruges called on Vinçotte's services in 2024 to check the boom cables of their pontoon crane, "Brabo".

Port of Antwerp-Bruges wanted a comprehensive examination of the boom cables that went beyond standard visual inspections. Given the height of the crane, even in the lowered position, our team had to operate from an aerial platform. The cable cross sections ranged from 82 mm to 107 mm, difficult to check with most conventional inspection equipment.

Thanks to advanced Magnetic Rope Testing technology, we delivered a thorough inspection.

Read more about it in our case study

Case study - DEME contacted Vinçotte in 2024 for inspection of the Sarens crane on the DEME ‘Neptune’ Ofshore Installation Vessel.

Equipped with Sarens' 600-tonne capacity Huisman crane, the vessel plays a pivotal role in the rapid deployment of offshore wind turbines and increasing green energy capacity. Vinçotte carried out a comprehensive magneto-inductive inspection of the crane's main, auxiliary and jib cables.

Thanks to Magnetic Rope Testing technology, we delivered a thorough inspection and identified defects in the cables that were previously undetected by visual inspection,

Read more about it in our case study

Case study - Borealis asked us to carry out a thorough inspection of their torch pipe in the harbour of Antwerp.

Next to the inspection of the extensive guy wires, we also carried out verticality and stress measurements on the 46m high flare pipe.

Our inspection led to the successful detection of potential problems and assurance of the structural integrity of the flare pipe. By identifying and addressing these issues early, we help Borealis prevent future operational disruptions and maintain standards.

What are the advantages of Magnetic Rope Testing (MRT)?

Focus on safety:

- MRT's ability to detect hidden defects significantly reduces the risk of catastrophic cable failures and protects lives, property and infrastructure.

- By identifying potential problems early, MRT enables you to address them proactively before they escalate into dangerous situations.

Predictive maintenance:

- MRT enables predictive maintenance, allowing you to proactively plan cable replacements based on accurate data and not just on visual inspections.

- This prevents unplanned downtime and costly repairs due to sudden failures.

Increased efficiency:

- Compared to traditional methods, MRT offers faster and more efficient inspections in many cases, minimising downtime.

- The reliable data obtained with MRT allows for longer intervals between replacements, reducing overall inspection time and costs.

Compliance:

- MRT is recognised as a reliable NDT method and helps you comply with industry regulations and safety standards such as ISO 4309, ensuring that your operations meet the highest safety standards.

Choosing MRT gives you a comprehensive understanding of the condition of your cables, allowing you to prioritise safety, optimise maintenance practices and achieve greater operational efficiency.

Conditions to ensure reliable results:

- Certified technicians: For accurate and reliable MRT results, it is crucial to use certified technicians who have the necessary training and expertise to operate the equipment and interpret the data. Vinçotte's MRT specialists have years of experience in Lifting inspections.

- Data interpretation: The data obtained with MRT requires expert analysis to translate the magnetic field fluctuations into meaningful insights about the condition of the rope. Experienced professionals understand the significance of different patterns and can accurately assess the severity of potential defects.

- Complementary approach: While MRT offers exceptional benefits, it is important to remember that it complements, not replaces, visual inspections. The combination of both methods provides a comprehensive assessment of rope health, ensuring that no aspect of the condition goes unnoticed.

By understanding these key points, you can maximise the effectiveness of MRT and make informed decisions regarding rope safety and maintenance.

Legal framework

Section 280 of the General Regulations on Labour Protection (ARAB) states that heavy lifting equipment must be inspected upon commissioning.

Article 281 states that wearing parts - including steel cables - must be inspected quarterly.

These inspections must be carried out visually according to the Vinçotte guideline approved by BELAC.

However, ISO standard 4309-2017 - which describes all guidelines for the installation, maintenance and inspection of steel wire ropes in cranes and hoists - recommends the use of MRT as an additional inspection on top of the statutory visual inspection for critical installations.

MRT (Magnetic Rope Testing) is the ideal solution for cable inspection of the following:

- Construction sector: tower cranes, mobile cranes

- Mining & quarrying: lifting systems and transport equipment

- Oil & gas: offshore platforms, drilling rigs, flare pipes

- Maritime and shipping: shipboard cranes, winches harbour cranes

- Storage and material handling: Conveyor systems, hoists and other material handling equipment in warehouses and production plants using steel wire rope

- Energy sector: winches for wind turbines, polar cranes, turbine hoists and lifts

- Infrastructure: Suspension and cable bridges, cable cars, skywalks and pedestrian bridges, ski lifts, transmission towers, roller coasters, Ferris wheels, freefall towers, ziplines

Interested in this solution? Contact us!

Contact

Ask your question directly to the specialised team within your sector.