Flanders imposes rigorous regulations for tank inspections to safeguard safety, the environment, and technical compliance. Under the supervision of the Department of the Environment and local environmental authorities, these regulations mandate periodic inspections of above-ground storage tanks containing hazardous substances, which must meet stringent standards and be carried out by recognised inspection bodies.

Comprehensive risk based approach

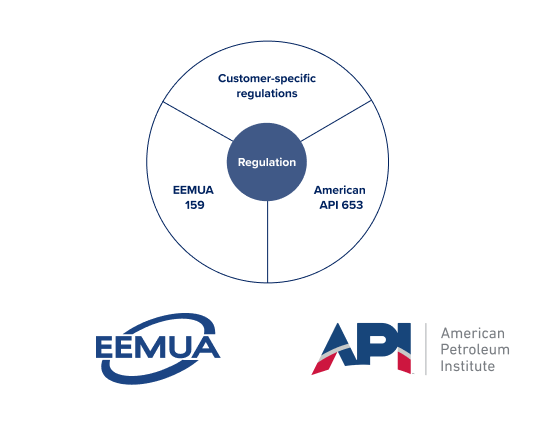

We base our broad tank inspection methodology on the American API 653 and EEMUA 159 codes to deliver a Comprehensive risk-based approach.

This approach not only ensures that all relevant inspections are carried out with precision but also that the risks associated with the equipment are effectively managed. By incorporating this methodology, we aim to safeguard both the structural integrity and operational safety of storage tanks.

We pride ourselves on being flexible and customer-centric, and when required, we perform tank inspections based on the customer’s own standards, always working closely with them throughout the process. This approach allows us to offer bespoke solutions that cater fully to the specific needs and expectations of our customers.

Process

#

05 #

Adjusting inspections and frequency #

Adjustments are made to the inspection procedures, techniques, or frequency when results indicate the need for changes. These adjustments may involve recommending further inspections or adapting the frequency of future inspections to meet both the results and the customer’s needs.